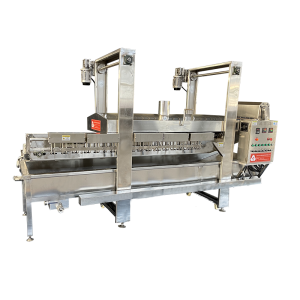

Mochini oa ho hadika oa khoho oa khoebo

1. Phetiso ea lebanta la letlooeng e amohela taolo ea lebelo le se nang mohato. Laola nako ea ho hadika ka bolokolohi.

2. Mochini oa ho hadika o na le sistimi ea ho phahamisa e iketsang, 'mele oa sekoahelo se kaholimo le lebanta la letlooeng li ka phahamisoa holimo le tlase, e leng se loketseng ho hloekisoa.

3. Mochini oa ho hadika li-nugget tsa khoho o na le sistimi ea ho hohla ka thoko ho ntša masala a hlahisoang neng kapa neng nakong ea ts'ebetso ea tlhahiso.

4. Sistimi ea ho futhumatsa e entsoeng ka mokhoa o ikhethileng e etsa hore katleho ea matla a mocheso e be holimo.

5. Motlakase, mashala kapa khase li sebelisoa e le matla a futhumatsang, 'me mochini oohle o entsoe ka tšepe e sa hloekang ea boleng ba lijo. E hloekile, e bolokehile, e bonolo ho e hloekisa, e bonolo ho e hlokomela le ho boloka tšebeliso ea mafura.

Tšepe e sa Khaotseng ea Lijo

Karolo e ka sehloohong ea mochini o hadikang o tsoelang pele e entsoe ka tšepe e sa hloekang ea boleng ba lijo, e bolokehileng le e hloekileng, tšepe e sa hloekang ea 304, e nang le phaephe ea motlakase e hahiloeng kahare bakeng sa ho futhumatsa, sekhahla se phahameng sa tšebeliso ea mocheso le ho futhumatsa ka potlako.

Ho Boloka Mafura le ho Fokotsa Litšenyehelo

Theknoloji e tsoetseng pele ea lehae e sebelisoa ho etsa hore sebopeho sa ka hare sa tanka ea oli se be se senyenyane, bokhoni ba oli bo bonyenyane, tšebeliso ea oli ea fokotseha, 'me litšenyehelo lia bolokoa.

Taolo ea Boiketsetso

Ho na le lebokose le ikemetseng la kabo, diparamente tsa tshebetso di setilwe esale pele, tshebetso yohle ya tlhahiso ya othomathiki, mme mmala le tatso ya sehlahiswa di a tshwana ebile di tsitsitse.

Sistimi ea ho Phahamisa ka Boiketsetso

Ho phahamisa kholomo ka boiketsetso ho ka etsa hore ho phahamisoe ha sekoaelo sa mosi le lebanta la letlooeng ho arohane kapa ho kopantswe, e leng se loketseng bareki ho hlwekisa le ho hlokomela disebediswa.

Lebanta la Letlooeng la Phetoho ea Lebelo la Maqhubu

Phetoho ea maqhubu kapa taolo ea lebelo le se nang mohato ea lebanta la letlooeng e sebelisoa ho fetisa lihlahisoa, tse loketseng litlhoko tsa ho hadika tsa mefuta e fapaneng.

Sistimi ea ho Tlosa Li-slag tse Habeli

Sistimi ea ho tlosa slag ka boiketsetso, sistimi ea ho tlosa slag ka potoloho ea oli, ho tlosa slag ha e ntse e hadika, ho lelefatsa bophelo ba ts'ebeletso ea oli e jeoang le ho boloka litšenyehelo tsa tšebeliso ea oli.

Mochini o sa khaotseng oa ho hadika li-nugget tsa khoho o loketse haholo lihlahisoa tse latelang: li-chips tsa litapole, li-french fries, li-chips tsa banana le lijo tse ling tse puffed; linaoa tse sephara, linaoa tse tala, linate tsa peanut le linate tse ling; raese e crispy, li-rice strips tse mafura, litsebe tsa katse, Shaqima, twist le lihlahisoa tse ling tsa noodle; nama, maoto a khoho le lihlahisoa tse ling tsa nama; Lihlahisoa tsa metsing tse kang croaker e mosehla le octopus.